Cellular Connectivity for Manufacturing: Keeping Production Lines Running

Every minute of manufacturing downtime costs money—and unreliable connectivity is often the hidden cause. Cellular connectivity gives manufacturers a resilient, rapidly deployable alternative to single-ISP networks, keeping production lines online even when wired connections fail. From primary wireless WAN to automatic failover, modern cellular solutions support smart factories, IoT, and cloud systems across dozens or hundreds of facilities. The result: higher uptime, faster deployments, and a stronger, more reliable production environment.

The Hidden Costs of DIY IoT Deployment And How to Avoid Them

DIY IoT deployments often look cheaper on paper—but hidden costs quietly erode ROI. Timeline overruns, internal labor drain, carrier complexity, and certification gaps can add six figures to multi-location projects. This article breaks down where those costs hide, why internal teams struggle at scale, and how managed IoT deployments reduce risk, accelerate timelines, and deliver better long-term performance without unexpected overhead.

Why Your Multi-Location Business Needs a Single Cellular Partner

Managing cellular connectivity across dozens or hundreds of locations quickly becomes expensive and complex when multiple carriers are involved. Fragmented billing, inconsistent rates, and scattered support drain time and budget from finance and operations teams. A single, carrier-agnostic cellular partner simplifies management by consolidating billing, optimizing coverage per location, and streamlining support. The result is lower costs, faster issue resolution, and scalable connectivity that supports growth without adding operational overhead.

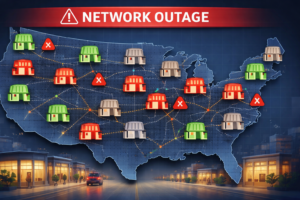

The True Cost of Network Downtime for Multi-Location Businesses

Downtime is expensive—but for multi-location businesses, the real cost is often hidden. When connectivity fails across multiple sites, lost revenue is only the beginning. Labor waste, customer defection, inventory spoilage, and operational disruption compound quickly. This article breaks down the true financial impact of network outages, explains why traditional backup connections fall short, and shows how managed cellular failover can dramatically reduce risk, protect revenue, and improve operational resilience at scale.

Cutting the Cord: Why Forward-Thinking Businesses Are Making 5G Their Primary Connectivity

Legacy wired networks quietly drain capital through maintenance, downtime, and facility constraints—especially across multi-location portfolios. Modern 5G has changed the equation. Today’s enterprise-grade wireless WAN solutions deliver the speed, reliability, and security required for primary connectivity while shifting spend from CAPEX to predictable OPEX. Forward-thinking organizations are cutting infrastructure costs, accelerating site launches, and simplifying facilities operations by replacing cables with carrier-agnostic 5G.

Smart Vending Goes Wireless: How Cellular Connectivity Transforms Industrial Tool Management

Smart vending machines can dramatically reduce lost productivity by eliminating time-consuming trips to centralized tool cribs—but only when they stay reliably connected. In industrial environments where Wi-Fi and wired networks fall short, cellular connectivity offers a flexible, infrastructure-free solution. This article explores how LTE and 5G power real-time inventory visibility, scalable multi-site deployments, and consistent ROI for operations leaders managing distributed manufacturing and logistics facilities.