Every minute a production line stands idle costs money. For manufacturers operating across multiple facilities, that equation multiplies fast — one connectivity failure at a single plant can cascade into missed shipments, spoiled inventory, and broken SLAs that damage customer relationships for months. The traditional approach of relying on a single wired ISP connection at each facility leaves manufacturers exposed to exactly this kind of disruption. Cellular connectivity offers a fundamentally different model: resilient, rapidly deployable wireless WAN solutions that keep production environments online regardless of what happens to landline infrastructure.

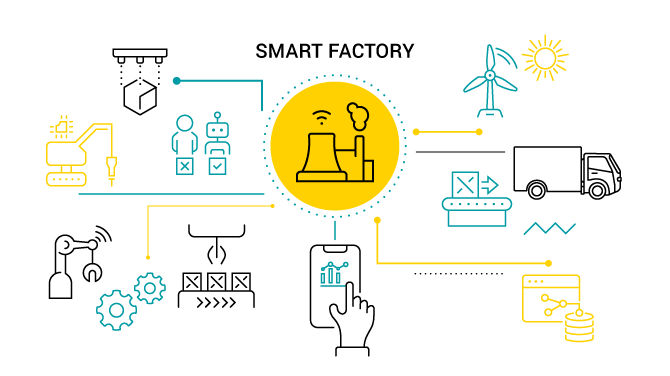

Manufacturing has emerged as one of the fastest-growing sectors for managed cellular deployments, and the reasons extend well beyond simple backup connectivity. Today's smart factories depend on a growing ecosystem of connected devices, real-time data streams, and cloud-based management platforms that demand reliable bandwidth at every facility. Understanding how cellular fits into this picture — and how to deploy it efficiently across dozens or hundreds of locations — is quickly becoming a competitive imperative.

The True Cost of Connectivity Downtime on the Factory Floor

Downtime calculations in manufacturing are staggering. Industry research consistently places the average cost of unplanned downtime for mid-size manufacturers between $50,000 and $260,000 per hour, depending on the sector and production volume. Automotive and pharmaceutical operations sit at the higher end of that range, while food and beverage or general assembly plants typically fall in the middle. Even at the conservative end, a four-hour outage at a single facility represents a $200,000 loss before accounting for overtime costs, expedited shipping to recover schedules, or contractual penalties.

What makes these numbers particularly painful is how often connectivity sits at the root cause. Modern manufacturing execution systems (MES), enterprise resource planning (ERP) platforms, and supervisory control and data acquisition (SCADA) networks all depend on reliable internet access to function properly. When the connection drops, it doesn't just mean employees can't check email — it means production scheduling goes dark, quality control data stops flowing, and automated inventory management loses visibility across the supply chain.

Manufacturers with 50 or more locations face compounded risk. A single ISP relationship per site creates 50 individual points of failure, each subject to fiber cuts, local outages, provider maintenance windows, and weather events. The probability that at least one facility experiences a connectivity disruption in any given month approaches near-certainty at that scale.

Why Cellular Changes the Reliability Equation

Cellular wireless WAN technology fundamentally alters the risk profile for manufacturing connectivity. Rather than depending on a single physical path — typically a buried fiber or copper line vulnerable to construction damage, flooding, and equipment failure — cellular connections leverage the existing tower infrastructure of major carriers. This creates path diversity that wired connections alone cannot provide.

Modern enterprise-grade cellular routers, particularly those built on platforms like Ericsson's Cradlepoint, deliver performance that would have been unimaginable five years ago. With 5G and advanced LTE capabilities, these devices routinely achieve speeds which rival cable internet — more than sufficient for most manufacturing applications including real-time video monitoring, cloud-based MES platforms, and IoT sensor data aggregation.

The deployment model matters just as much as the technology. Cellular solutions can be operational within hours rather than the weeks or months required for new fiber installations. For manufacturers opening new facilities, expanding production capacity, or standing up temporary operations, this speed-to-deployment translates directly into faster revenue generation. A plant that comes online three weeks earlier because it didn't have to wait for a fiber build represents significant financial upside.

Primary and Failover: Building True Redundancy

The most resilient manufacturing connectivity strategies use cellular in two distinct roles. As a primary connection, cellular serves facilities where wired infrastructure is unavailable, unreliable, or prohibitively expensive to install — a common scenario for plants in industrial parks, rural areas, or recently constructed buildings where fiber hasn't yet been extended. As a failover connection, cellular provides automatic backup when the primary wired link goes down, ensuring production systems never lose connectivity.

Hybrid deployments that pair a wired primary with cellular failover deliver the highest levels of uptime. When the wired connection experiences degradation or failure, traffic automatically shifts to the cellular link with zero manual intervention. Many enterprise cellular platforms support sub-second failover, meaning production applications experience little to no disruption during the transition. Operations teams may not even realize a failover event occurred until they review network logs.

For multi-location manufacturers, this architecture eliminates the single-point-of-failure problem entirely. Each facility maintains two independent connectivity paths using completely different physical infrastructure. The wired connection and the cellular connection share no common failure modes — a backhoe cutting fiber has zero impact on the cellular link, and a carrier tower issue doesn't affect the wired circuit.

Supporting the Connected Factory Ecosystem

Cellular connectivity plays an increasingly critical role beyond simple internet access. Modern manufacturing facilities generate massive volumes of data from IoT sensors, automated quality inspection systems, environmental monitoring equipment, and robotic process controls. All of this data needs to reach cloud platforms for analysis, storage, and integration with enterprise systems.

Facilities deploying smart manufacturing technologies often discover that their existing wired connections lack the bandwidth headroom to support new IoT workloads alongside existing business traffic. Cellular provides an elegant solution — dedicated wireless bandwidth for IoT and operational technology (OT) traffic, separated from the corporate network to improve both performance and security. This segmentation aligns with cybersecurity best practices that manufacturing organizations are increasingly required to follow.

Edge computing deployments benefit from cellular connectivity as well. Processing data locally at the factory edge reduces latency for time-sensitive applications like machine vision quality control or predictive maintenance algorithms. Cellular links provide the reliable upstream connectivity these edge nodes need to synchronize with central cloud platforms, push alerts, and receive updated machine learning models.

Managing Cellular at Scale: The Multi-Location Challenge

Deploying cellular connectivity at a single facility is straightforward. Managing it across 50, 100, or 500 manufacturing locations introduces complexity that can overwhelm internal IT teams already stretched thin by day-to-day operations. Each site requires carrier selection based on local coverage strength, appropriate data plan sizing, hardware provisioning, installation coordination, and ongoing monitoring — multiplied across every facility in the network.

Carrier relationships alone become a significant administrative burden at scale. Different locations may require different carriers based on regional coverage quality, meaning a manufacturer with national operations could end up managing relationships with three or four cellular providers simultaneously. Each carrier has its own billing cycles, support processes, contract terms, and escalation procedures. Without a consolidation strategy, the operational overhead of managing these relationships can consume 15 to 20 hours per week of IT staff time — time that could be directed toward strategic projects that drive business growth.

This is precisely where ISP aggregation becomes transformative for manufacturing organizations. Working with a single managed connectivity partner that handles carrier relationships, data plan optimization, hardware lifecycle management, and centralized monitoring across all locations collapses the complexity into a single point of contact. Billing consolidation alone typically saves manufacturers between $27,000 and $45,000 annually in administrative costs, while centralized monitoring ensures every facility's connectivity health is visible from a single dashboard.

Financial Advantages Beyond Uptime

The financial case for cellular connectivity in manufacturing extends well beyond avoiding downtime losses. Shifting from capital-intensive fiber installations to operational expense-based cellular subscriptions improves cash flow predictability and reduces the upfront investment required to bring new facilities online. A typical fiber build for an industrial facility runs between $15,000 and $50,000 depending on distance and site conditions, with lead times of 30 to 90 days. Cellular deployment costs a fraction of that amount and delivers connectivity within days.

Flexible data plans also allow manufacturers to right-size their connectivity spend based on actual usage patterns. Facilities with lighter bandwidth requirements — warehouses, distribution centers, or low-volume production sites — can operate on smaller plans rather than paying for fiber capacity they don't fully utilize. This granular cost control across a large facility portfolio typically yields 20 to 35 percent savings compared to provisioning every location with identical wired circuits.

Manufacturers evaluating total cost of ownership should also factor in the reduced need for on-site technical support. Cloud-managed cellular platforms enable remote troubleshooting, firmware updates, and configuration changes without dispatching technicians. For organizations with geographically dispersed facilities, this remote management capability can reduce site visit costs by 40 percent or more annually.

Getting Started: A Practical Path Forward

Manufacturers considering cellular connectivity should begin with a comprehensive assessment of their current connectivity landscape. This means cataloging every facility's existing ISP relationships, bandwidth utilization, uptime history, and planned technology deployments that may increase connectivity demands. Facilities with the weakest uptime records or highest downtime costs represent natural starting points for cellular deployment.

Partnering with a managed connectivity provider that specializes in multi-location cellular deployments accelerates the process significantly. The right partner brings carrier-agnostic expertise — selecting the optimal carrier and plan for each facility based on actual coverage data rather than marketing claims — along with centralized management tools that provide real-time visibility across the entire network. Certified partnerships with leading hardware manufacturers like Ericsson Cradlepoint ensure that the equipment deployed at each site is enterprise-grade, purpose-built for demanding industrial environments, and backed by comprehensive support.

Production doesn't wait for connectivity problems to resolve themselves, and manufacturers shouldn't have to either. Cellular technology has matured to the point where it delivers the reliability, performance, and scalability that modern manufacturing demands. The organizations that recognize this shift and act on it will operate with a level of connectivity resilience that becomes a genuine competitive advantage — keeping production lines running, supply chains moving, and customers satisfied regardless of what happens to any single network link.